Lined Reducing Tee

Lined Reducing Tee Specification

- Type

- Lined Reducing Tee

- Material

- Ductile Iron/Carbon Steel body with PTFE/FEP/PFA lining

- Working Temperature

- -20C to +180C (depends on lining material)

- Density

- 2.2 Gram per cubic centimeter(g/cm3)

- Corrosion Protection

- Full PTFE/FEP/PFA lining for chemical resistance

- Tensile Strength

- 2030 MPa (PTFE lining)

- Thickness

- Lining: 3 mm or as per client request

- Melting Point

- 327C (PTFE)

- Size

- 1 3/4 to 12 10 (Standard NB)

- Width

- Varies by NB and size specification

- Length

- According to ASME/ANSI dimensions

Lined Reducing Tee Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10-15 Days

- Main Domestic Market

- Manipur, Bihar, Punjab, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

About Lined Reducing Tee

- Lined : PFA, FEP, PVDF, PP, HDPECasting : D.I. Casting as per ASTM A 395, Gr.60-40-18

- For Febrication : Sch. 10, Sch. 20, Sch. 30, Sch. 40, Sch. 60, Sch. 80, Sch. 100, Sch. 120, Sch. 140, Sch. 160

- Flange Rating : Rotating, Fixed On/Off Centers-ASME B 16.5 - Cls. 150, Cls.300, Cls. 600, BS 10, Table E, Table F, Table H, Table j & Table K, Din Standard- PN6, PN10, PN16, PN25, PN40

- Geometry: Non standard Dimensions.

Superior Chemical Resistance

The lined reducing tee boasts a full PTFE, FEP, or PFA lining that provides high resistance against acids, alkalies, solvents, and aggressive gases. This makes it highly suitable for chemical processing, ensuring long-term reliability and reducing the risk of corrosion-related failures.

Versatile Design and Sizing

With flanged ends conforming to ANSI, DIN, or customized standards, as well as a variety of pressure ratings and size options, this tee offers great flexibility. It accommodates different piping systems and fluid handling requirements, making it a versatile choice for process industries.

Durability and Safety

The external epoxy or powder coating, combined with a durable ductile iron or carbon steel body, provides excellent mechanical strength and enhanced protection against environmental factors. The non-stick, smooth internal lining also helps prevent scale buildup and contamination, supporting efficient operation.

FAQ's of Lined Reducing Tee:

Q: How does the lined reducing tee protect against corrosion?

A: The lined reducing tee is fully lined internally with PTFE, FEP, or PFA, which acts as a barrier against corrosive chemicals, acids, and solvents. This lining prevents any aggressive fluids from contacting the metal body, ensuring long-term resistance to corrosion and chemical attack.Q: What fluids are suitable for use with this reducing tee?

A: It is designed for safe transfer of acids, alkalies, solvents, corrosive liquids, and various gases. The PTFE/FEP/PFA lining provides compatibility with a broad spectrum of chemicals typically found in industrial and chemical processing environments.Q: When should a lined reducing tee with flanged ends be used?

A: This product is recommended when your process line requires a branch connection with a reduced outlet, especially where fluids are highly corrosive or chemically aggressive. The flanged connections make it suitable for secure installation and easy maintenance in industrial piping systems.Q: Where can these tees be installed?

A: Lined reducing tees are commonly used in chemical plants, pharmaceutical manufacturing, water treatment facilities, and any industry dealing with hazardous or corrosive fluids. Their robust construction is suitable for both indoor and outdoor installations.Q: What is the manufacturing process for the internal lining?

A: The internal lining is bonded to the tee's metal body through a precise molding or paste extrusion process, ensuring a seamless, smooth, and securely anchored layer of PTFE, FEP, or PFA inside the fitting to maximize chemical resistance and non-stick characteristics.Q: How does the anti-corrosive internal finish benefit system performance?

A: The smooth, non-stick internal lining significantly reduces the risk of scale, deposits, or blockages forming inside the tee. This promotes a steady fluid flow, minimizes contamination risk, and makes cleaning and maintenance easier.Q: What are the advantages of choosing custom color or flange specifications?

A: Customization in color ensures easy identification and adherence to plant standardization, while custom flange options facilitate seamless integration into existing piping setups, reducing installation time and ensuring optimal system compatibility.

Price 1200 INR/ Piece

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10-15 Days

- Main Domestic Market

- Manipur, Bihar, Punjab, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MS PTFE Lined Pipe And Fitting Category

Tubular Sight Glass

Price 2000 INR / Unit

Minimum Order Quantity : 100 Units

Size : Standard

Material : SS & Glass

Type : Sight Glass

Corrosion Protection : Yes

Black MS Steam Trap

Price 5000 INR / Unit

Minimum Order Quantity : 10 Units

Size : Standard

Material : MS

Type : Black MS Steam Trap

Corrosion Protection : Yes

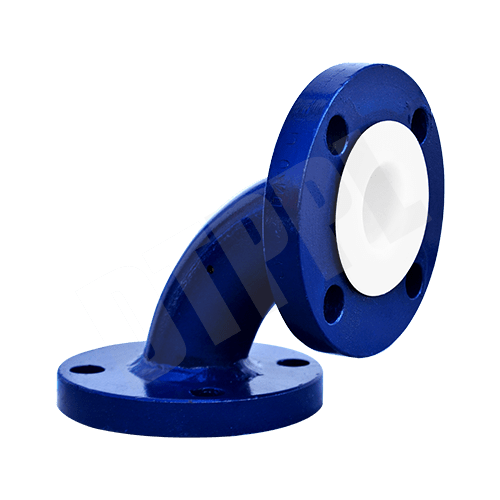

Lined Elbow 90 deg

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Size : Different Available

Material : PTFE

Type : Lined Elbow

Corrosion Protection : Yes

Lined Full View Sight Glass

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Size : Standard

Material : SS

Type : Lined Full View Sight Glass

Corrosion Protection : No