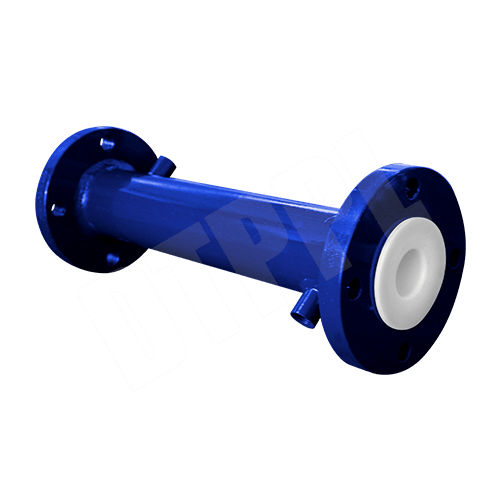

Lined Hose Pipe

Lined Hose Pipe Specification

- Type

- Lined Hose Pipe

- Material

- PTFE (Polytetrafluoroethylene) Lining with SS Braiding

- Working Temperature

- -40C to +180C

- Density

- 2.15 Gram per cubic centimeter(g/cm3)

- Corrosion Protection

- Excellent resistance to chemicals and corrosion

- Tensile Strength

- 25 MPa

- Thickness

- 2 mm to 4 mm

- Melting Point

- 327C

- Size

- 1 inch to 6 inch

- Width

- 25 mm to 150 mm

- Length

- Up to 10 meters

Lined Hose Pipe Trade Information

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- Manipur, Bihar, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

About Lined Hose Pipe

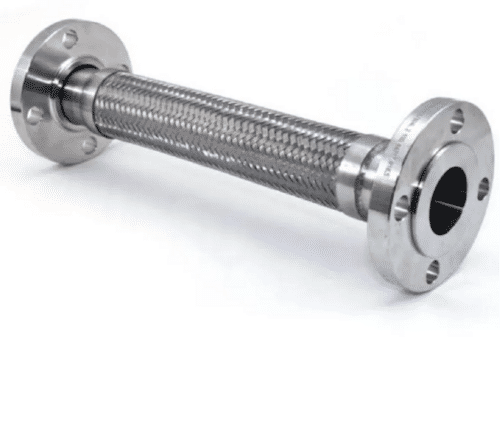

- Lining: PTFEHose Pipe: SS 304, SS 316, SS 316L

- Braiding : SS 304, SS 316, SS 316L

- Flange : SS 304, SS 316, SS 316L

- ASME B 16.5 - Cls. 150, Cls. 300, Cls. 600.

- Flange Rating : BS 10- Table D, Table E, Table F, Table H, Table J & Table K DIN Standerd - PN6, PN10, PN16, PN 25, PN40.

Exceptional Chemical and Corrosion Resistance

The PTFE lining in our hose pipe offers remarkable chemical resistance, protecting against a wide spectrum of corrosive materials. This makes it particularly advantageous in industries dealing with aggressive chemicals, as well as in pharmaceutical and food-grade processes where purity and hygiene are paramount.

Flexible Design With Robust Construction

Our lined hose pipes balance high flexibility with structural integrity, thanks to their stainless steel braided exterior. This construction allows the hose to maintain flexibility even in confined or dynamic spaces without compromising strength or safety.

FAQs of Lined Hose Pipe:

Q: How is the PTFE lined hose pipe installed in industrial systems?

A: The PTFE lined hose pipe can be easily installed using its end connection options, including flanged, threaded, or tri-clamp types. Select the appropriate connection type based on your existing system setup. Securely attach the hose according to industrial standards to ensure a leak-proof and reliable fit.Q: What makes this hose suitable for chemical, pharmaceutical, and food industries?

A: This hose features a 100% virgin PTFE lining, giving it superior resistance to chemicals and corrosion, while also being inert, which is essential for contamination-free processes in chemical, pharmaceutical, and food industry applications.Q: Where can these hose pipes be used within a facility?

A: Lined hose pipes are suitable for areas where the transfer of corrosive or high-purity fluids is necessary. Typical applications include chemical dosing lines, pharmaceutical processing, and the transfer of food-grade products.Q: What are the benefits of stainless steel (SS304/SS316) braiding on the hose?

A: The stainless steel braiding significantly enhances the hoses mechanical strength, flexibility, and fire resistance. It also provides an extra layer of protection against external physical damage and temperature fluctuations.Q: When should the PTFE lined hose pipe be replaced?

A: It is advisable to inspect the hose periodically for signs of wear, mechanical stress, or chemical attack. Replacement is recommended if there are visible cracks in the PTFE lining, reduced flexibility, or compromised end connections, ensuring safety and performance.Q: How does this hose pipe comply with international safety standards?

A: The hose pipe is manufactured to meet ASTM and ISO certification requirements, ensuring it adheres to rigorous quality, safety, and reliability standards expected in global industrial applications.

Price 1000 INR/ Piece

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- Manipur, Bihar, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS PTFE Lined Pipe And Fitting Category

Lined Jacketed Spool

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Jacketed Spool, Lined

Material : Carbon Steel/SS316 with PTFE/FEP/PFA Lining, Mild Steel outer jacket

Size : DN25 to DN600 or as per specification

Thickness : Lining thickness 2.5 mm to 5 mm, Jacket thickness per ASME standard

Cast Steel Double Glass Inspection Window

Price 2000 INR / Piece

Minimum Order Quantity : 10 Units

Type : Cast Steel Double Glass Inspection Window

Material : Cast Steel

Size : Standard

Thickness : 25 Millimeter (mm)

MS PTFE Sight Glass

Price 2000 INR / Unit

Minimum Order Quantity : 10 Units

Type : MS PTFE Sight Glass

Material : Mild Steel

Size : Different Size

Thickness : As per available Millimeter (mm)

Lined Full View Sight Glass

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Type : Lined Full View Sight Glass

Material : SS

Size : Standard

Thickness : 3.5 Millimeter (mm)