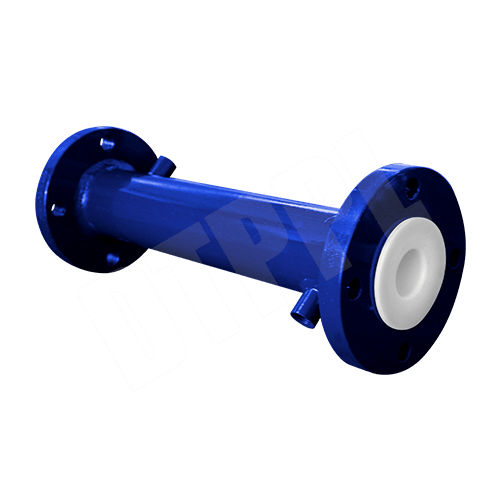

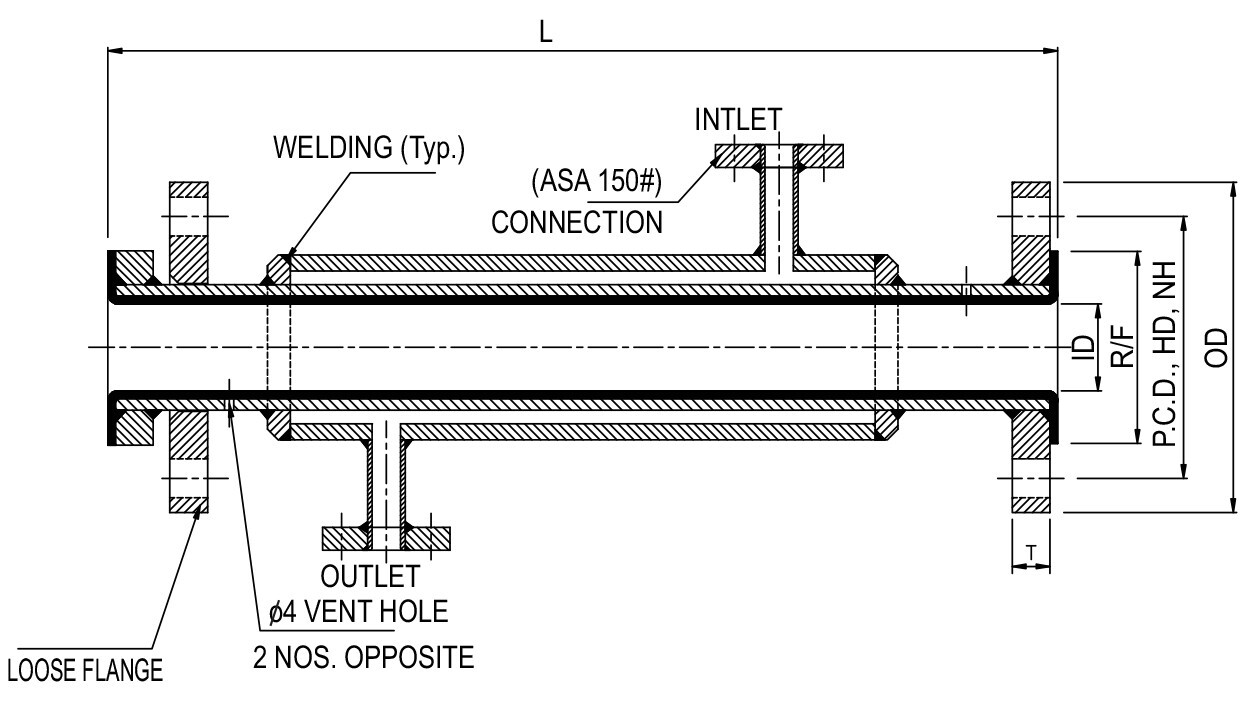

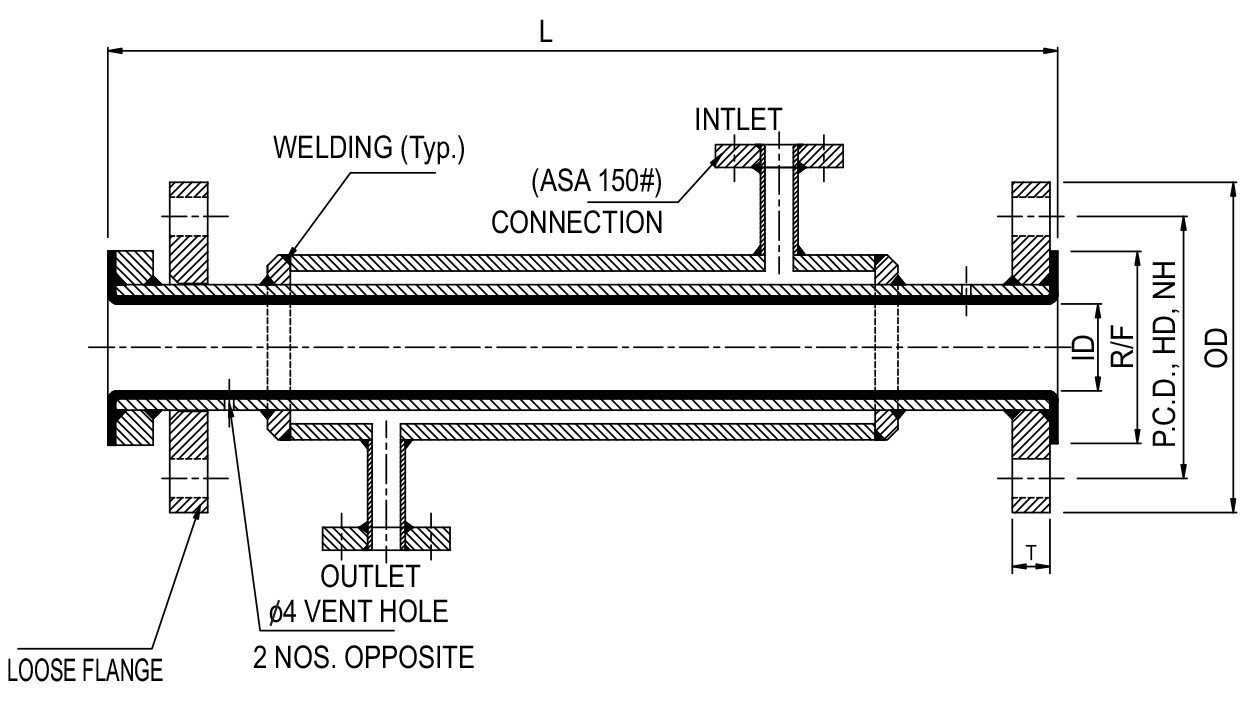

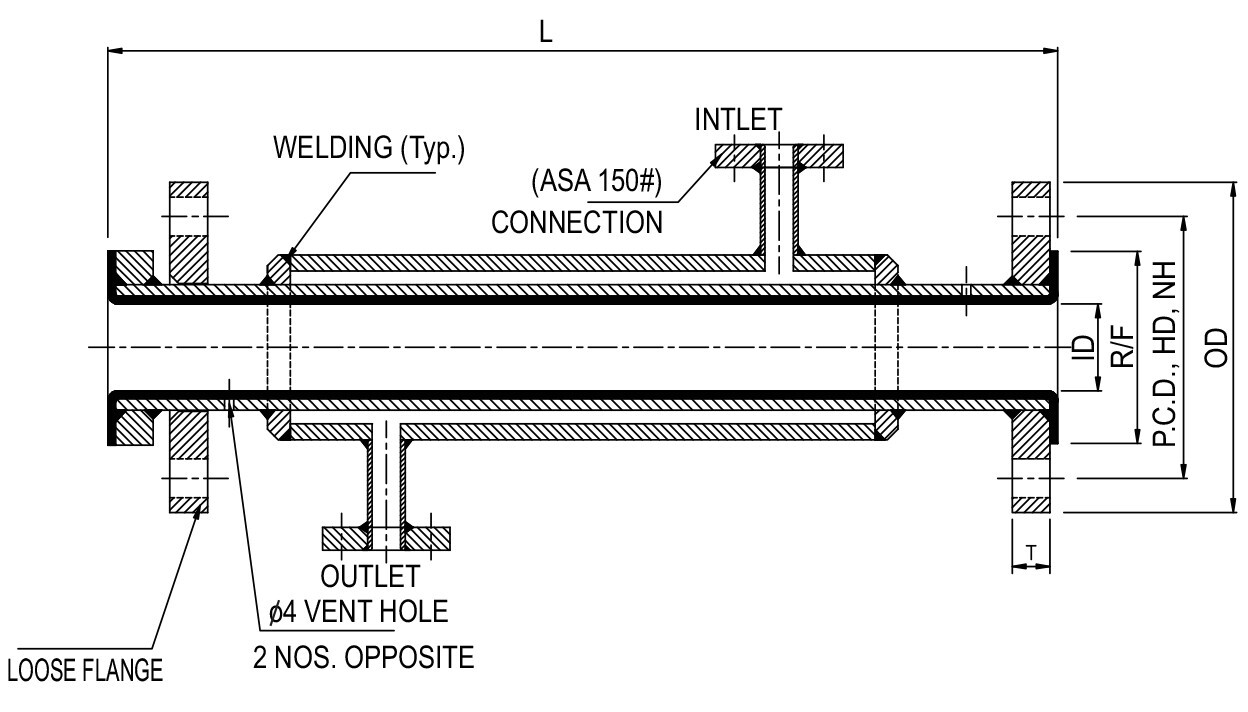

Lined Jacketed Spool

Lined Jacketed Spool Specification

- Type

- Jacketed Spool, Lined

- Material

- Carbon Steel/SS316 with PTFE/FEP/PFA Lining, Mild Steel outer jacket

- Working Temperature

- -20C to 200C based on lining material

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection

- Excellent (suitable for aggressive chemicals)

- Tensile Strength

- 28-35 MPa

- Thickness

- Lining thickness 2.5 mm to 5 mm, Jacket thickness per ASME standard

- Melting Point

- 327C

- Size

- DN25 to DN600 or as per specification

- Width

- Custom as per pipe schedule (typically DN25 to DN600)

- Length

- Custom fabrication (typically 150 mm to 3000 mm)

Lined Jacketed Spool Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10-15 Days

- Main Domestic Market

- Manipur, Bihar, Punjab, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

About Lined Jacketed Spool

- Lining : PTFE, PP, HDPE, PVDF, Antistatic

- Pipe : ASTM A 106 Gr. B, SS 304, SS 316, SS 316L

- Pipe Schedule - Sch 10, Sch 20, Sch 30, Sch 40, Sch 60, Sch 80, Sch 100, Sch 120, Sch 140, Sch 160

- Flange Rating - ASME B 16.5-Cls.150, Cls.300, Cls.600,

- BS 10-Table D,Table E,Table F,Table H,Table J &Table k

Versatile Lining Material Options

Choose from premium lining materials-PTFE, PFA, or FEP-to suit specific chemical compatibility requirements. Each fluoropolymer offers outstanding resistance to a wide range of corrosive substances, enabling reliable operation even with the most demanding fluids. This flexibility ensures you can select the most suitable lining based on chemical process needs and operational temperatures.

Robust Construction for Demanding Applications

The jacketed spools are fabricated from high-grade carbon steel or stainless steel for the outer layer, ensuring mechanical strength. The internal lining provides a seamless chemical barrier, while the external jacket can be epoxy painted or custom coated for added protection. Standard and custom sizes (DN25 to DN600, lengths up to 3000 mm) are available to match your piping system.

Application-Oriented Design and Testing

Designed primarily for industries handling corrosive or temperature-sensitive substances, these spools conform to rigorous testing standards (ASTM/DIN) such as hydrostatic and spark tests. Optional leak detection ports enhance safety, and flanged ends as per ANSI B16.5 / DIN / JIS / IS standards facilitate easy integration into existing systems.

FAQ's of Lined Jacketed Spool:

Q: How do I choose the right lining material for my jacketed spool?

A: Selecting the appropriate lining-PTFE, PFA, or FEP-depends on the specific chemicals being conveyed and the operating temperature. Each material provides excellent corrosion resistance, but their chemical compatibility and temperature limits may vary. Consult your supplier's compatibility chart or technical resources to determine the best fit for your application.Q: What benefits does a lined jacketed spool offer when conveying corrosive or temperature-sensitive chemicals?

A: A lined jacketed spool combines mechanical strength with outstanding chemical protection, ensuring safe transportation of corrosive or temperature-sensitive fluids. The double-layer design prevents chemical attack on the steel jacket, offers temperature control, and minimizes contamination, which extends equipment life and reduces maintenance costs.Q: When should leak detection ports be considered for lined jacketed spools?

A: Leak detection ports are recommended in critical applications where early identification of lining failure is essential for safety and environmental protection. This feature is available on request and helps users monitor and maintain system integrity, particularly in hazardous chemical processes.Q: Where are lined jacketed spools typically used?

A: These spools are commonly used in chemical processing, pharmaceutical manufacturing, petrochemical plants, and other industries dealing with aggressive or sensitive fluids. Their customizable design allows integration into various pipeline systems that require high levels of corrosion resistance and temperature management.Q: What is the standard process for testing lined jacketed spools before delivery?

A: Each product undergoes rigorous hydrostatic and spark testing, in line with ASTM and DIN standards. Hydrostatic tests verify the spool's pressure integrity, while spark tests ensure the lining is completely free of pinholes or defects, guaranteeing reliable and leak-free operation after installation.Q: How can I specify custom features, such as color or external coating, for my order?

A: Custom options, including color of the external jacket and specific coating types, can be specified at the time of order. Discuss your requirements with your supplier or trader, who can advise on available customizations to meet project or corporate standards.

Price 1500 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10-15 Days

- Main Domestic Market

- Manipur, Bihar, Punjab, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS PTFE Lined Pipe And Fitting Category

Lined Concentric Reducer

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Carbon Steel/SS with PTFE/FEP/PFA Lining

Size : 1 to 12 (DN25 to DN300)

Type : Lined Concentric Reducer

Thickness : Lining thickness 35 mm

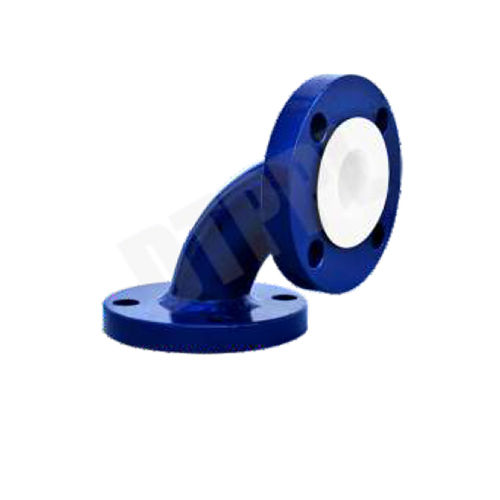

90 Degree MS PTFE Elbow

Price 1000 INR / Unit

Minimum Order Quantity : 10 Units

Material : Mild Steel

Size : Different Size

Type : 90 Degree MS PTFE Elbow

Thickness : As per available Millimeter (mm)

Lined Full View Sight Glass

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : SS

Size : Standard

Type : Lined Full View Sight Glass

Thickness : 3.5 Millimeter (mm)

Lined Ball Valve

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : SS

Size : Standard

Type : Lined Ball Valve

Thickness : 3.5 Millimeter (mm)