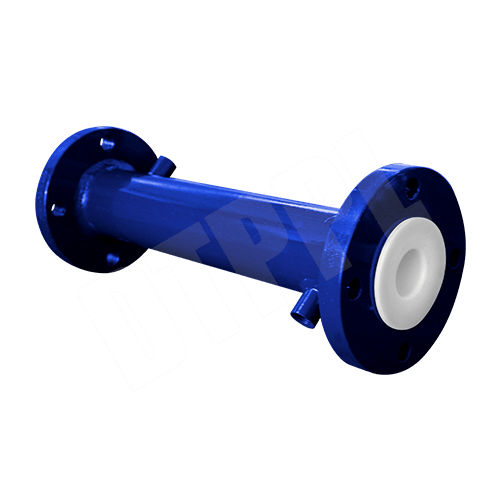

Lined Concentric Reducer

Lined Concentric Reducer Specification

- Type

- Lined Concentric Reducer

- Material

- Carbon Steel/SS with PTFE/FEP/PFA Lining

- Working Temperature

- -29C to +200C

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection

- PTFE/FEP/PFA Lining

- Tensile Strength

- 21 - 30 MPa

- Thickness

- Lining thickness 3-5 mm

- Melting Point

- 327C

- Size

- 1 to 12 (DN25 to DN300)

- Width

- Custom as per design

- Length

- Standard or as per requirement

- Surface Finish

- Shot Blasted and Painted

- Color

- Standard white lining, external color as per project

- Outer Body Material

- Carbon Steel ASTM A 106 Gr B or Stainless Steel ASTM A312

- Leak Test

- 100% Hydro Test and Spark Test

- Inner Lining Material Options

- PTFE, FEP, PFA

- End Connection

- Flanged as per ASME B16.5 / DIN / JIS

- Application

- Chemical, Pharmaceutical, Petrochemical Industries

- Applicable Standards

- ASTM F1545, DIN 2848

- Design Pressure

- 10 to 16 bar

Lined Concentric Reducer Trade Information

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- Manipur, Bihar, Punjab, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

About Lined Concentric Reducer

- Lining : PFA, FEP, PVDF, PP, HDPECasting : D.I. Casting as per ASTM A 395, Gr. 60-40-18

- For Febrication : Sch. 10, Sch. 20, Sch. 30, Sch. 40, Sch. 60, Sch. 80, Sch. 100, Sch. 120, Sch. 140, Sch. 160.

- Flange Rating: Rotating, Fixed On/Off Centers - ASME B 16.5 - Cls.150, Cls. 300, Cls. 600, BS 10 - Table D, Table E, Table F, Table H, Table J & Table K DIN Standard-PN6, PN10, PN16, PN25, PN 40.

Robust Construction and Advanced Lining

Our lined concentric reducers are crafted from high-grade carbon steel or stainless steel, lined with PTFE, FEP, or PFA for excellent chemical resistance. The lining thickness ranges from 3 to 5 mm, protecting against corrosive media. The outer surface is shot blasted and painted, with external color customizable to your project requirements, ensuring both durability and aesthetic compliance.

Wide Range of Industrial Applications

Designed specifically for chemical, pharmaceutical, and petrochemical industries, these reducers adapt seamlessly to pipelines requiring corrosion protection and reliable flow transition between varying diameters. Their design supports working temperatures from -29C to +200C and can withstand pressures up to 16 bar, making them ideal for aggressive and demanding service conditions.

FAQ's of Lined Concentric Reducer:

Q: How is the lined concentric reducer with flanged ends tested for leakage?

A: Each reducer undergoes a 100% hydrostatic leak test as well as a spark test on the lining, ensuring absolute system integrity under specified pressures and operational conditions.Q: What are the benefits of using PTFE, FEP, or PFA linings in these reducers?

A: PTFE, FEP, and PFA linings provide excellent resistance to corrosive chemicals, extending the service life of the reducer and reducing maintenance costs. These materials also handle a wide temperature range and offer a high degree of non-stick properties, minimizing process contamination.Q: Where are these reducers commonly used?

A: These reducers are widely implemented in chemical, pharmaceutical, and petrochemical industries where reliable corrosion protection and safe media transfer between pipe sections of different sizes are critical.Q: What is the standard process for installing a lined concentric reducer with flanged ends?

A: Installation involves aligning the flanged ends with the existing pipeline flanges as per the ASME B16.5, DIN, or JIS standards, using compatible gaskets and bolts. Care should be taken to avoid damaging the lining during installation.Q: When should a lined concentric reducer be selected over an unlined one?

A: A lined reducer should be chosen when handling aggressive or corrosive media, high purity applications, or where contamination must be minimized. The lining provides a protective barrier, ensuring process integrity.Q: What customization options are available for these reducers?

A: Customers can specify width, length, and external color according to project requirements. Various sizes from DN25 to DN300 are available, and both standard and custom dimensions can be accommodated based on pipeline design.

Price 1000 INR/ Piece

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- Manipur, Bihar, Punjab, Delhi, Arunachal Pradesh, Haryana, Madhya Pradesh, Rajasthan, Sikkim, Uttar Pradesh, Uttarakhand

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS PTFE Lined Pipe And Fitting Category

Lined Reducing Tee

Price 1200 INR / Piece

Minimum Order Quantity : 10 Pieces

Size : 1 3/4 to 12 10 (Standard NB)

Material : Ductile Iron/Carbon Steel body with PTFE/FEP/PFA lining

Type : Lined Reducing Tee

Tensile Strength : 2030 MPa (PTFE lining)

Lined Jacketed Spool

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Size : DN25 to DN600 or as per specification

Material : Carbon Steel/SS316 with PTFE/FEP/PFA Lining, Mild Steel outer jacket

Type : Jacketed Spool, Lined

Tensile Strength : 2835 MPa

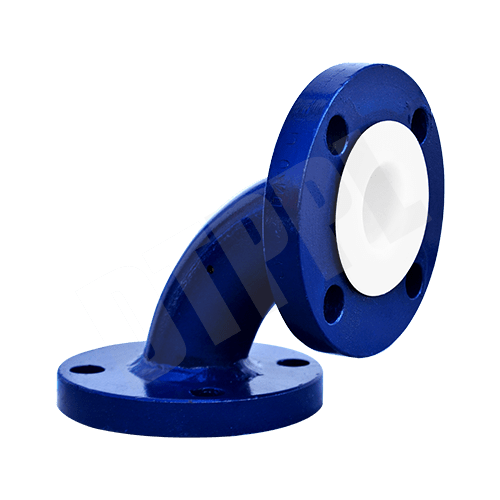

Lined Elbow 90 deg

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Size : Different Available

Material : PTFE

Type : Lined Elbow

Tensile Strength : 25 Kilopascals (KPa)

MS PTFE Equal Cross

Price 800 INR / Unit

Minimum Order Quantity : 10 Units

Size : Different Size

Material : Mild Steel

Type : MS PTFE Equal Cross